Drying equipment is Electroplating equipment The first key component, Electroplating equipment manufacturer The key machinery and equipment for drying and drying steel parts include drying box and hydrogen removal box, drying tank, heating fan, suction filter dryer equipment, drying oil tank, drying service platform, etc.

1、 Drying box

Drying oven is usually used to dry the cleaned steel parts after electroplating. Some steel parts need to be dehydrogenated after electroplating. Generally, the electric heated blast drying oven with good temperature uniformity is used as the drying equipment. If it is simply used to dry steel parts, the drying oven with steam heating can be selected.

Application and Maintenance of Electric Drying Oven

1. Frequently check whether the grounding wire is firm and reliable;

2. Remove the steel parts and waste falling from the box several times a week;

3. During application, pay attention to check whether the measuring and adjusting equipment of electric contact thermometer is reliable;

4. Before the steel parts are put into the drying box, a part of the accumulated gold water in the concave shape of the steel parts shall be poured in first. For the final hand washing, try to use boiled water.

2、 Dry bath

The dry tank is mainly used for production lines or assembly lines with professional driving, and the temperature is usually 65~75 ℃. There are two key heating methods:

1. With the help of natural heat convection and radiation source heating, heating tubes are set on the outer wall and bottom of the tank, which is simple in structure, but the heating efficiency is not high and the temperature is low;

2. The dry tank with blower motor usually adopts the warm air circulation system, that is, add a flat and vertical tank cover on the tank, the gas is sent through the blower motor, and then through the steam heat pipe radiator to the tank body, and then through the upper part of the tank, the blower motor is sucked in, and then according to the heat pipe radiator, the tank body circulation system is heated. The dry and dry temperature can be as high as hg75 ℃, and the dry and dry efficiency is high, Resources are saved, but the plating tank structure is complicated. If there is a higher requirement for the cleanliness of the steel parts when they are dry, a filter system can be added at the suction port of the centrifugal fan.

3、 Heating fan

The heating fan is a drying equipment for electroplated parts with simple structure, high drying efficiency and low noise. It can replace air compression drying with this kind of machinery and equipment. Hanging steel parts in front of the ordinary heating fan can only achieve good dry and practical effect.

4、 Suction filter dryer equipment

The suction filter dryer uses centripetal force to dry and dehydrate the surface of the steel parts. After the electroplating process steel parts are washed with boiling water, they are put into the basket of the centrifugal dehydrator while hot, and drive the rotary drum of the centrifugal dehydrator at a moderate speed ratio to drive the basket and steel parts to rotate. The introduction of warm air into the centrifugal dehydrator can speed up the whole drying process. When the centrifugal dehydrator is used to dry and flatten steel parts (such as sealing rings) and bowl shaped steel parts, it should be started several times to continuously dehydrate, so as to avoid uneven dryness caused by the mutual bonding machine.

Application and maintenance of suction filter dryer

1. After the steel parts are cleaned by boiling water, put them into the basket of the dehydrator while they are hot, rotate them at a moderate speed ratio, and rely on the centripetal force to dry the steel parts;

2. The dehydrator shall be maintained frequently, and the lubrication position shall be oiled frequently to clean, operate freely and the brake pedal shall be flexible;

3. The steel parts should not be loaded into the dryer too full. Before starting, the outer cover should be covered and the surrounding of the dehydrator should be cleaned to prevent the steel parts or other objects from being thrown out and causing death;

4. When loading the basket, it must be carried out after the centrifugal dehydrator completely stops rotating, and it must not be forced to stop when the centrifugal dehydrator rotates.

5、 Oil dehydration tank

Only the ordinary steel tank is needed for the drying oil tank, and a drain valve is set at the bottom of the plating tank, which is simple in structure and saves resources. The dehydrated oil can absorb the water on the surface of the steel parts into the oil, and then the water sinks to the bottom of the tank. Opening the drain valve can only discharge the water at the bottom of the tank.

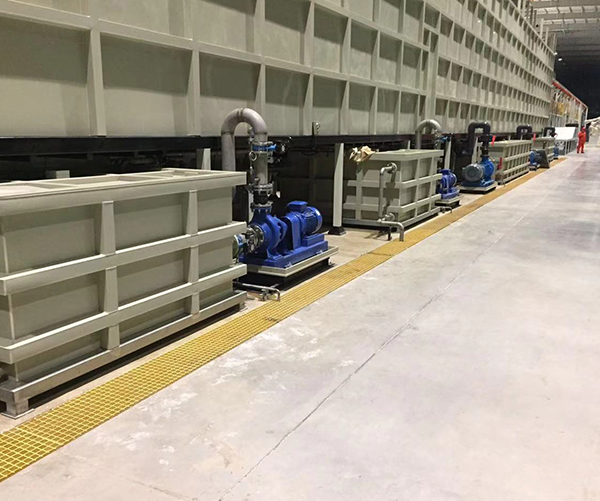

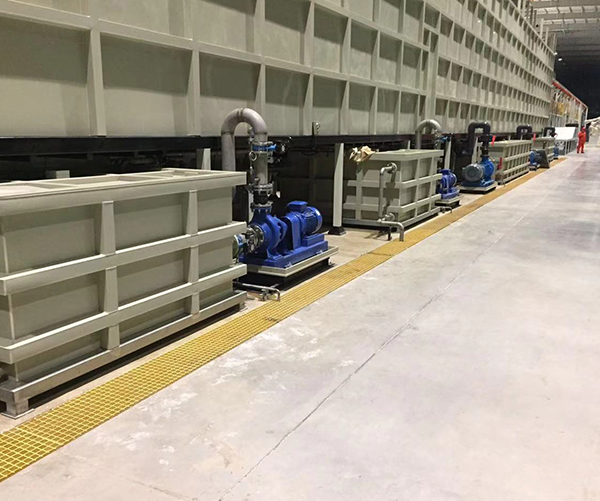

6、 Dry service platform

The drying service platform is a more simple and practical drying equipment in electroplating equipment. It can be retrofitted with a warming fan on the grid service platform with gauze, or it can be a service platform with a steam bobbin. After being scalded by hot water, the steel parts after electroplating process can be immediately placed on the dry service platform. Clean air can be compressed to blow purified water while air drying in many ways. Steel parts with complicated appearance can be rolled manually to avoid water in steel parts.