Drying equipment is Electroplating equipment As one of the important components, the equipment for dehydration and drying of electroplated workpieces mainly includes drying boxes and hydrogen removal boxes, drying tanks, air heaters, centrifugal dryers, dehydration oil tanks, drying platforms, etc.

1、 Drying oven

Drying after electroplating generally uses a drying oven to dry the cleaned workpieces, and some workpieces need to be dehydrogenated after electroplating. Generally, electric blast drying oven with good temperature uniformity is used as drying equipment. If it is only used for drying workpieces, steam heating oven can be used.

Use and maintenance of electric drying oven

1. Frequently check whether the ground wire is firm and reliable;

2. Clean the falling workpieces and dirt in the box once a week;

3. When using, pay attention to check whether the measuring and adjusting device of electric contact thermometer is reliable;

4. Before the workpiece is put into the drying box, the accumulated water in the concave part of the workpiece shall be poured out first. For the last wash, use hot water as much as possible.

2、 Drying tank

Drying tank is mainly used for production line or automatic line with mechanized crane, and the temperature is generally 60~70 ℃. There are two main heating methods:

1. Relying on natural convection and radiation heating, heating tubes are set on the inner wall and bottom of the tank, which is simple in structure, but not high in heating efficiency and low in temperature;

2. The drying tank with blower generally adopts the form of hot air circulation, that is, a flat open tank cover is added to the tank, the air is sent into the tank through the blower, and then enters the tank through the steam radiator, and then is sucked into the blower on the upper side of the tank, and then enters the tank through the radiator for circulation heating. The drying temperature can reach 70 ℃, the drying efficiency is high, and the energy is saved, However, the structure of plating tank is complex. When there is a high requirement for the cleanliness of the workpiece during drying, a filter device can be added at the suction port of the fan.

3、 Heater

The air heater is a drying equipment for electroplated parts with simple structure, high drying efficiency and low noise. It can be used instead of compressed air for drying. A good drying effect can be obtained by hanging the workpiece in front of the general fan heater.

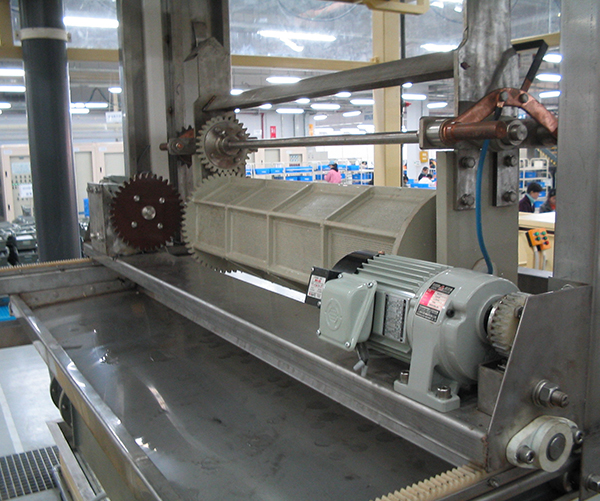

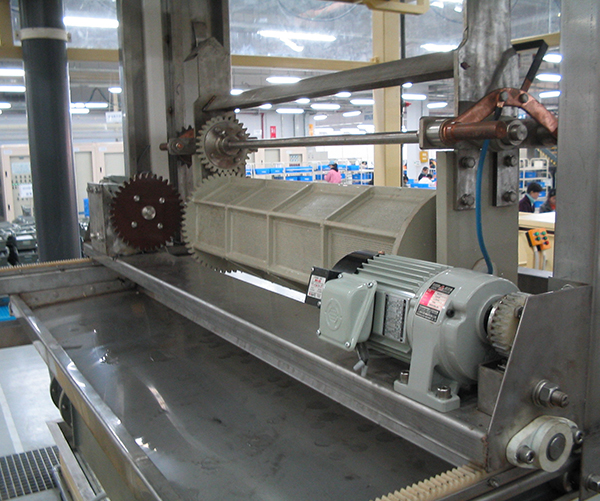

4、 Centrifugal dryer

The centrifugal dryer uses centrifugal force to dehydrate and dry the surface of the workpiece. After hot water ironing, the electroplated workpiece is loaded into the basket of the centrifuge while it is hot, and the rotating cylinder of the centrifuge is driven at an appropriate speed to drive the basket and workpiece to rotate. The drying process can be accelerated by introducing hot air into the centrifuge. When the centrifuge is used to dry flat workpieces (such as washers) and bowl shaped workpieces, it should be started for many times and repeatedly dumped to prevent uneven drying due to mutual binding.

Use and maintenance of centrifugal dryer

1. After the workpiece is washed with hot water, the workpiece is loaded into the basket of the dryer while it is hot, rotated at a proper speed, and dehydrated and dried with the help of centrifugal force;

2. The dryer shall be maintained frequently, and the lubricating parts shall be oiled frequently to keep clean, operate freely, and brake flexibly;

3. The workpiece should not be loaded into the dryer too full. Before starting, the cover must be covered and the surrounding area of the dryer must be cleaned to avoid injuries caused by throwing out the workpiece or other objects;

4. When reclaiming the basket, it must be carried out after the centrifuge completely stops rotating. Never force the centrifuge to stop rotating.

5、 Dehydration oil tank

The dehydration oil tank only needs a general steel tank for drying, and a drain valve is set at the bottom of the plating tank, which is simple in structure and energy saving. The dehydrated oil can absorb the water on the surface of the workpiece into the oil, and then the water sinks to the bottom of the groove. Open the drain valve to drain the water at the bottom of the groove.

6、 Drying platform

The drying platform is the most simple and easy to operate drying equipment in electroplating equipment. It can be equipped with air heater on the grid platform with mesh or the platform with steam jacket. Plated workpieces can be directly placed on the drying platform after being scalded with hot water. Clean compressed air is used to blow clean water while drying. The workpieces with complex shapes can be turned manually to prevent water accumulation in the workpieces.