Organic waste gas absorption tower generally refers to activated carbon absorption tower, which is a kind of waste gas absorption tower. It is a purification tower for absorbing organic waste gas. The organic waste gas absorbed by it contains benzene, toluene, xylene, non methane total hydrocarbon, VOCs (volatile organic compounds), methanol, tin and its compounds and other organic gases. Therefore, it is often used for exhaust gas purification in spray booth.

Acid mist purification tower, also known as acid mist absorption tower, belongs to the category of waste gas absorption tower. The acid mist absorbed by it includes sulfuric acid mist (H2SO4), nitric acid mist (HNO3), hydrogen chloride (HCL) gas, hydrogen fluoride (HF) gas, chromic acid mist (CrO3), hydrogen cyanide (HCN) gas, hydrogen sulfide (H2S), etc. Therefore, it is often used for purification in the pickling workshop.

Organic waste gas absorption tower generally refers to activated carbon absorption tower, which is a kind of waste gas absorption tower. It is a purification tower for absorbing organic waste gas. The organic waste gas absorbed by it contains benzene, toluene, xylene, non methane total hydrocarbon, VOCs (volatile organic compounds), methanol, tin and its compounds and other organic gases. Therefore, it is often used for exhaust gas purification in spray booth.

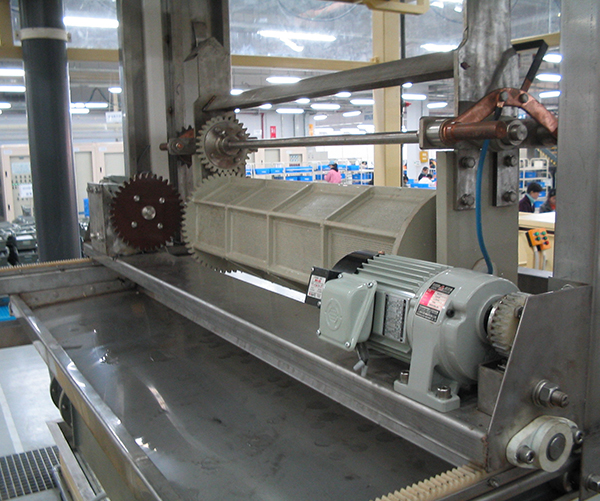

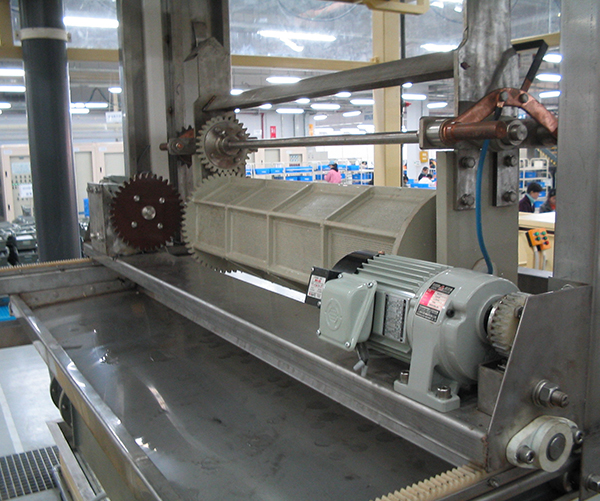

Electroplating equipment The acid mist purification tower is equipped with a fan and a water pump, usually a vertical tower, which neutralizes the acid mist with sodium hydroxide. The organic waste gas absorption tower is equipped with a fan, not a water pump, but a horizontal tower, which uses activated carbon to absorb organic waste gas.

Before the final equipment, the acid mist purification tower shall be subject to comprehensive corrosion resistance and acid inspection. If defects and deformations are found, they shall be repaired before equipment installation. The absorption tower needs to be installed on the concrete foundation, consistent with the horizontal line of the concrete foundation. The assembled absorption tower must be straight. During the assembly of absorption tower, flanges of each department shall be sealed to prevent gas overflow and liquid leakage. After the acid mist purification tower is completed and put into operation, the sundries and dirt in each circulation system shall be carefully checked and removed to avoid blocking. When using the absorption tower, special personnel must be assigned to handle it, and the ventilation system, liquid circulation system and liquid spraying equipment must be checked regularly to see if they are abnormal. If any undesirable phenomenon is found, it shall be handled in time. Our products use the latest high-tech packing, which has the characteristics of small resistance loss, large specific surface area, perfect chemical reaction, reasonable gas-liquid ratio, high absorption and purification efficiency, good corrosion resistance and aging resistance, and easy equipment protection. If it is used in northern winter, anti freezing measures shall be taken for tower bottom pool.