Electroplating equipment Use efficiency of

Now an efficient and fast electroplating equipment can simultaneously plate multiple workpieces. In addition, the liquid medium is stirred during the electroplating process, so that the workpiece electroplating can be accelerated. At the same time, the liquid medium is extracted from the electroplating box to filter out impurities while stirring electroplating, and the purity and quality of electroplating are always adhered to, which greatly improves the efficiency of electroplating and is a high-efficient and fast electroplating equipment.

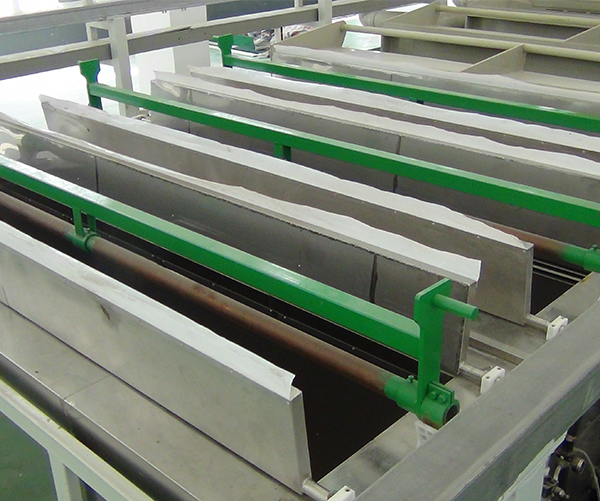

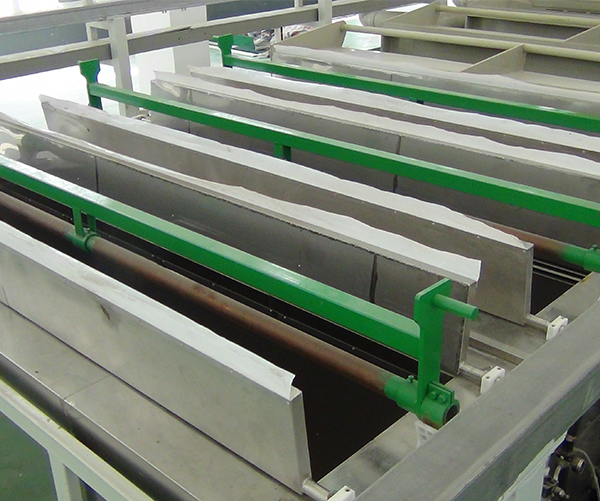

The electroplating box includes the electroplating box, impurity filter screen and agitator. The electroplating box is placed on the rack, and the upper end is placed with the electroplating box cover and sealed at the contact point. The upper end of the electroplating box cover is provided with several negative poles and electroplating workpieces, and the lower end of the negative pole and electroplating workpieces extends into the electroplating box.

The electroplating box is filled with liquid medium for electroplating. The lower end of the negative pole and the electroplating workpiece is immersed in this liquid. The lower end of the electroplating box is equipped with a row of agitators. The blades of the agitators are partially in the liquid medium, and the drive is partially fixed on the rack.

One end of the electroplating box is equipped with a pipette, the connection between the electroplating box and the pipette is equipped with a one-way valve, the other end of the pipette is connected with the lower end of the impurity filter screen, the upper end of the impurity filter screen is connected with a liquid pumping pump, the output end of the liquid pumping pump is connected with the electroplating box through the discharge pipe, and the impurity filter screen and the liquid pumping pump are placed on the pump support seat, The pump support seat is fixed on the outer side of the electroplating box.