Electroplating wastewater treatment equipment What maintenance techniques are needed

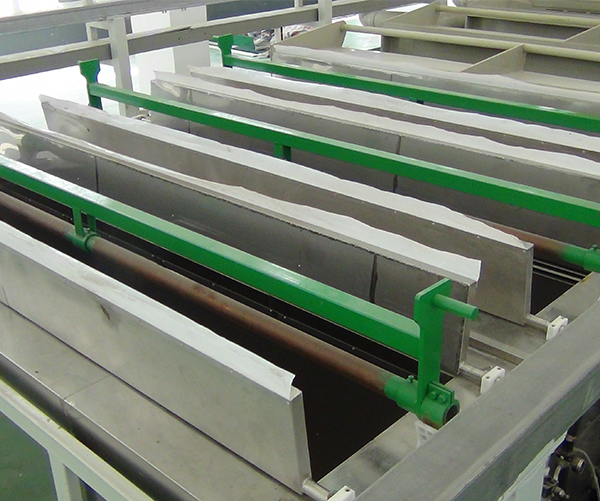

Only the plating line equipment with good maintenance skills for plating parts and hangers in the plating factory can guarantee the qualified process method, Electroplating equipment There is an inseparable relationship between the quality of galvanized parts and the quality of galvanized parts. Finally, high-quality plated parts are obtained. It is inevitable that some minor problems will occur in the temporary use of electroplating line equipment. The following is the main maintenance skill for electroplating hangers on the electroplating production line: workpiece assembly and reassembly. To ensure the appearance and brightness of the workpiece, use a knife to cut the insulation layer attached to the connection between the electroplating hanger and the workpiece. Do not touch the injured workpiece to prevent scratches and deformation.

Electroplating factory is a typical high energy consumption and high pollution industry, but it is also an extremely important part of surface treatment. The existing technology of electroplating industry cannot be replaced. Therefore, upgrading and transformation of electroplating enterprises is the only way for development. Now, in order to facilitate supervision, some places have established new electroplating industry concentration areas to integrate local electroplating enterprises. Small electroplating machines that could have survived in the crevice are facing such a development scenario. If they want to survive under the general trend of green and environmental protection, small electroplating equipment manufacturers must also make corresponding adjustments.

Check whether the electroplating machine is aged, deformed and discolored, and whether the insulation of the hanger is damaged. Whether it is electric leakage, whether it can be reused, if it is not damaged, it can be retained for use, if it has been damaged, it must be withdrawn. In case of an accident in the workshop, do not burn the insulator on the hanger with an open flame. Fire occurs. Attention shall be paid to safety technology and labor maintenance: ① ventilation facilities shall be provided at the assembly site; ② Wear gloves during assembly. c Pay attention when removing insulation materials. Avoid damage to skin; ③ Temporary convulsions.

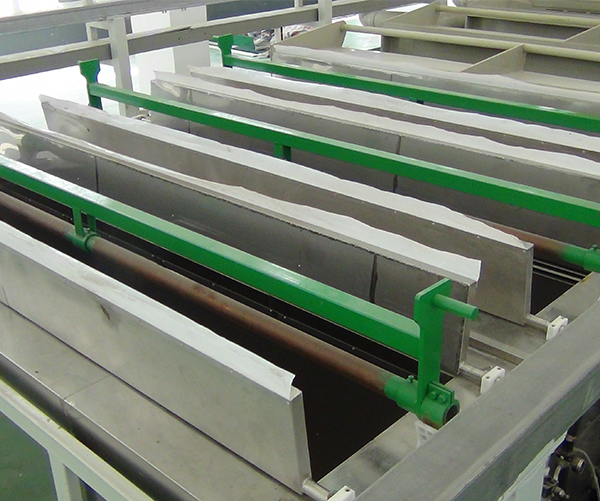

Gas mask shall be worn during the assembly of electroplating equipment. In case of failure. The metal ions in the plating solution of the electroplating machine are deposited on the surface of the workpiece by DC current, forming a uniform and dense metal coating. The condition required for electrodeposition is to apply a DC power supply. Electroplating equipment manufacturers use electrolytic method to treat the surface of the workpiece. The plated parts are cathode. The plating solution, electroplating and anode constitute an electrolytic equipment.

Electroplating factory is a high-frequency switching power supply used in the early 1990s. It is a new type of component with high quality, stable and reliable operation, and perfect self maintenance function and automation. If the conservative pre repair and maintenance mode is still adopted, not only the hidden dangers cannot be found, but also some man-made faults are caused by repeated assembly. In engineering practice, there are also cases of damage caused by assembly. Data analysis should be carried out frequently, and various information recorded by the computer of the switching power supply should be printed regularly, so that the historical information of the power supply itself can be easily understood, such as what happened to the AC interruption, when to charge and discharge the battery, and the current operating condition of the electroplating power supply. After analyzing these data, some problems can be found, such as the price of electroplating equipment needs to be adjusted in time so that it can be adjusted in time.