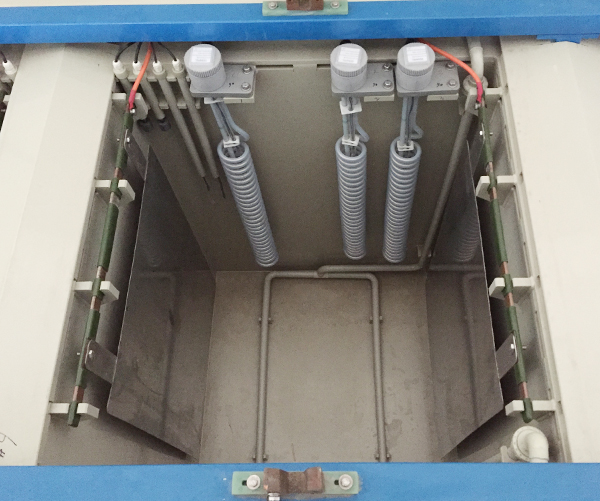

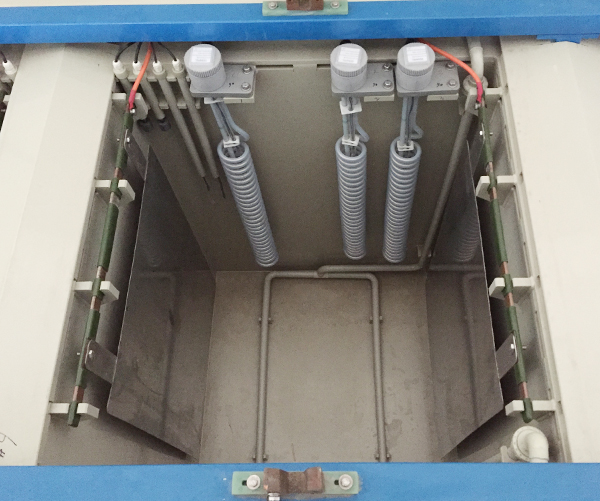

Electroplating equipment It is an important production equipment in the electroplating industry, which is used to coat the surface of metal materials with a layer of metal or alloy to improve their corrosion resistance, conductivity and aesthetics. There are several key points in selecting suitable equipment and controlling costs.

At first, learn about different types of electroplating equipment. According to different electroplating methods and process requirements, electroplating equipment can be divided into various types, including film pasting electroplating equipment, electrolytic electroplating equipment, chemical plating equipment, hot dip plating equipment, etc. When selecting equipment, first you need to determine your own plating method and process, and then select appropriate plating equipment according to these requirements.

Secondly, consider the quality and performance of the equipment. The quality and performance of electroplating equipment are directly related to product quality and production efficiency. When selecting equipment, you can judge the quality of the equipment by checking the manufacturer's qualification and product quality certification of the equipment. In addition, you can also know the technical parameters of the equipment, such as production capacity, energy consumption, degree of automation, etc., to determine whether the equipment meets your needs.

Third, consider the price and maintenance cost of the equipment. The price of equipment is one of the main considerations when enterprises choose equipment. The price of electroplating equipment of different brands and models is different, so you need to choose the appropriate equipment according to your own budget. In addition to the equipment price, it is also necessary to consider the maintenance cost of the equipment, including the energy consumption, maintenance costs, and consumables costs of the equipment. Maintenance cost control is very important for reducing production costs and improving enterprise competitiveness.

Fourth, choose reputable suppliers with good after-sales service. When selecting equipment, it is very important to choose a reputable supplier with good after-sales service. The reputation of suppliers can be learned from their reputation in the industry, customer evaluation, etc. Suppliers with good after-sales service can provide timely technical support and maintenance services to ensure the normal operation of equipment. In addition, suppliers can also provide equipment training and technical support to help enterprises better use equipment.

In addition, the use and maintenance of equipment shall be planned reasonably. After purchasing the equipment, it is necessary to formulate a reasonable plan for the use and maintenance of the equipment. Normal use and maintenance of equipment can extend the service life of equipment and reduce the probability of failure. In addition, reasonable planning of equipment use can also reduce energy consumption and production costs. It can be implemented by formulating equipment use and maintenance manuals, conducting regular equipment maintenance, and training operators.

In a word, selecting suitable electroplating equipment and controlling costs need to consider many factors, such as equipment type, quality and performance, price and maintenance cost, supplier reputation and after-sales service. Through reasonable planning and use of equipment, enterprises can reduce electroplating costs, improve production efficiency and enhance competitiveness.