Pretreatment before spraying The general pretreatment process of the pickling spray system is as follows:

Degreasing - water washing - surface adjustment - leather film - water washing (flexible adjustment according to workpiece characteristics).

The pre-treatment is divided into three forms: spray type, immersion type and submersible type. The treatment method is selected according to the workpiece and specific production requirements.

1. Spray type

The spray treatment method uses the spray principle to make the liquid medicine continuously act on the surface of the workpiece. It has strong working continuity and high efficiency. It is suitable for the requirements of large quantities of operations. The treatment effect is good. It is suitable for large pipe fittings, long pieces and items with simple structure. In general, it uses a high frame structure to save ground space.

2. Diving

The submersible treatment method is to immerse the workpieces into the swimming pool by means of hanging empty chains for treatment in the liquid medicine pool. It is suitable for the treatment of objects with complex shapes, and has good effect and saves the amount of liquid medicine

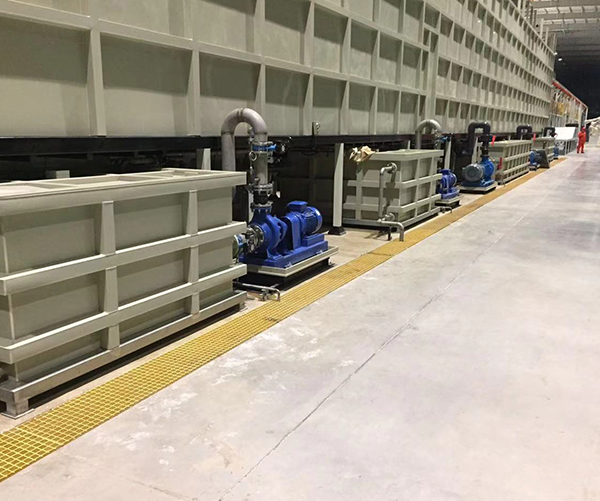

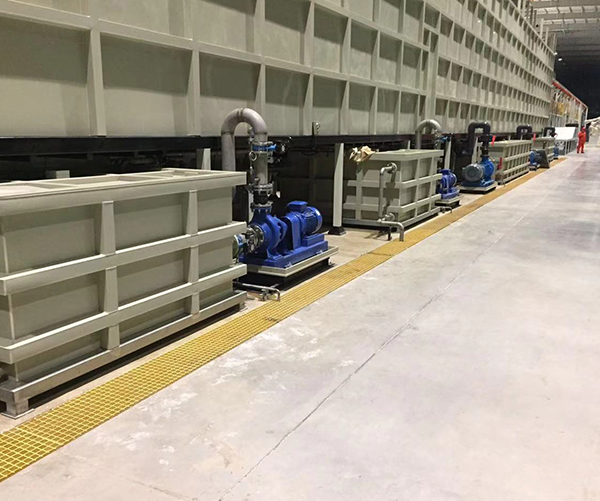

3. Immersion type

Immersion treatment is to use the crown block to lift the workpiece into the liquid medicine pool, and complete the surface treatment of the workpiece through physical and chemical methods. It is suitable for degreasing of workpieces with complex surface and serious rust, and the gas pipe is set in the film tank. The treatment solution can be stirred. According to the specific situation of the workpieces, a heating device can be set in the liquid medicine tank to improve the treatment efficiency. The setting is simple