Do you understand Electroplating equipment Magnetron sputtering coating technology

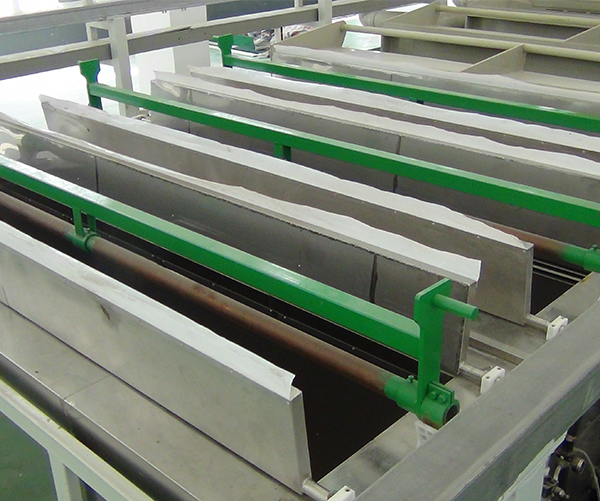

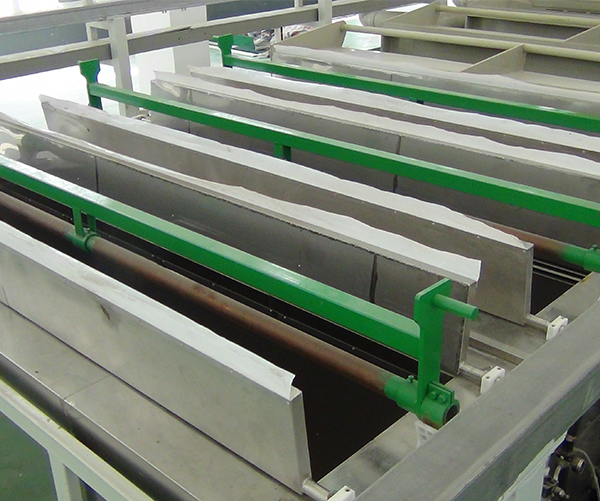

Magnetron sputtering coating equipment is a vacuum coating machine with simple structure and good electrical control stability. The selection of technology has a very important impact on the performance of the film. Today we will talk about magnetron sputtering coating technology.

The process flow of magnetron sputtering coating technology in ceramic surface decoration is as follows:

Ceramic chips → ultrasonic cleaning → clamping → background vacuum pumping → plasma cleaning → heating → argon gas injection → pre sputtering → background vacuum pumping → sputtering (or multiple sputtering) → AF film plating → vacuum breaking unloading → surface inspection → performance test → packaging and warehousing.

The above process technology is based on the magnetron sputtering coating equipment, selecting appropriate target materials and sputtering process to prepare super hard wear-resistant coatings, which can achieve the high hardness, high wear resistance and high scratch resistance of materials; At the same time, using the structural design of NCVM optical film, different refractive index materials of each layer are designed, which can be mixed into any color, making ceramics not only have high hardness, high strength, fashionable and beautiful appearance, but also not shield electromagnetic signals.

The magnetron sputtering coating equipment with NCVM process can realize the surface decoration treatment of ceramic electronic consumer goods. While ensuring the strength and hardness of ceramics, it can also improve their beauty and artistry, and better meet the personalized needs of consumers. NCVM coating is mainly used to convert metal materials through corresponding physical and chemical means under vacuum conditions, adsorbing on the material surface in the form of particles to form a coating layer. Compared with ordinary vacuum electroplating, NCVM has higher technology content and more complex processing flow.

Magnetron sputtering super hard film, combined with NCVM optical coating technology, has excellent wear resistance, corrosion resistance, coating thickness uniformity and high density, and has been widely used in electronic products. With the rapid development of the electronic industry, NCVM coating, by virtue of its superior performance, stands out in the field of vacuum electroplating technology and has become a core technology in the production of consumer electronics. While ensuring good treatment effect, it can also eliminate the harm of heavy metals to human bodies during electroplating and solve the environmental pollution problem.