Electroplating equipment How to perform routine check management?

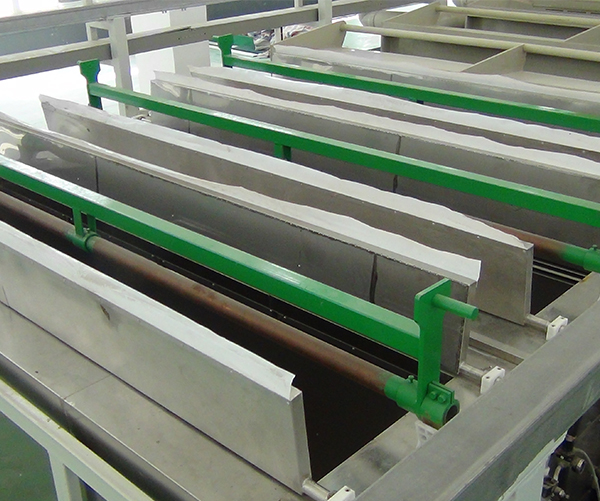

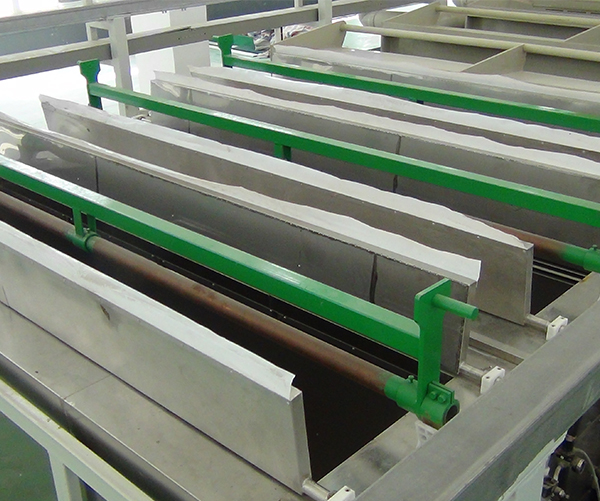

1、 Electroplating equipment manufacturer The electroplating equipment shall be under the network monitoring status, and the operation of the equipment shall be mastered to avoid the occurrence of sudden common faults. Mechanical equipment parts shall be used to a large extent to ensure the smooth progress of product quality and production.

2. Check the scheme of electroplating equipment to closely combine equipment maintenance with production and manufacturing, improve the efficiency of mechanical equipment, and ensure that all production and manufacturing are carried out normally.

3. Repair and maintain electroplating equipment to increase the service life of machinery and equipment.

4. Let employees master the structure of electroplating equipment according to the maintenance theme activities of electroplating equipment, improve their professional skills and professional skills in the maintenance of electroplating equipment, build their enthusiasm for valuing electroplating equipment, and gradually realize the management method of all personnel of electroplating equipment.

Patrol inspection of electroplating equipment shall be undertaken by the equipment maintenance management unit of the electroplating processing company. With regular maintenance as the core, check the required position of electroplating equipment according to certain specifications and cycle time, timely find safety risks, and temporarily carry out various repairs and adjustments to ensure the stable working characteristics of electroplating equipment.

The electroplating equipment patrol inspection management station has strong technical and professional ability, has a new project for routine patrol, and is also a timely system software inspection and replacement, that is, scheduled maintenance of mechanical equipment. The technical and professional quality of relevant personnel is high. The basic elements that should be followed in the routine maintenance of electroplating equipment are as follows:

① Check and determine the new items one by one according to the spot check list.

② Fill in the information spot check form according to the specified marks.

③ Record the position of deterioration tendency, pay attention to observation and carry out inspection appropriately.

④ In January, the problems in the spot check table were statistically analyzed and reported to the competent department of mechanical equipment, so as to facilitate the formulation of maintenance plans and the maintenance of mechanical equipment.