Electroplating wastewater treatment equipment What are the methods of

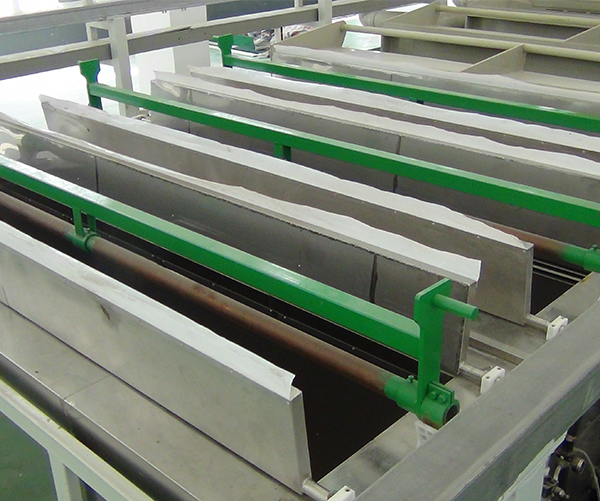

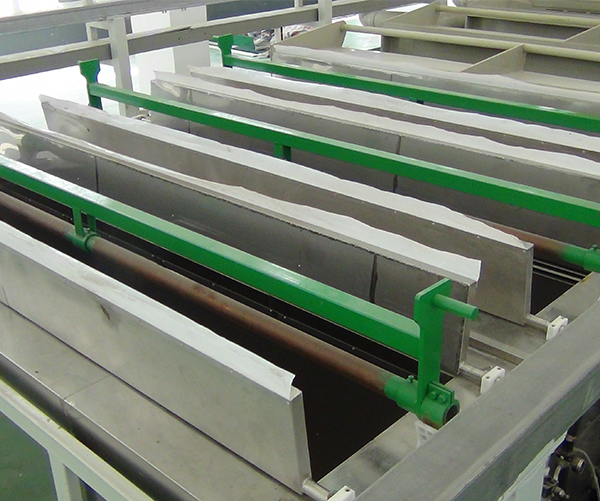

The purpose of electroplating wastewater treatment equipment is to make the wastewater reach the discharge standard and prevent environmental pollution around. It is impossible to talk about all the functions if the ultimate goal cannot be achieved. According to the complexity of such waste water sources, comprehensive and comprehensive treatment methods should be adopted. Large particle sundries, some organics and floating particles should not only be settled through sedimentation, filtration and adsorption, but also the most effective filtration method should be selected to quickly and thoroughly treat wastewater.

The function of electroplating wastewater treatment equipment itself is to purify and remove pollutants generated in the production process of electroplating industry. If secondary pollution occurs again in the process of wastewater treatment, this is a very unsatisfactory method. Reasonable design, small floor area, automatic control, automatic operation, no need for special personnel to handle. The purchase cost of electroplating wastewater treatment equipment is not only limited to the first purchase cost, but also considers the future maintenance and use costs. The lower the purchase cost, the better.

What kind of plating solution does the general electroplating factory use? This is mainly based on the choice of plating solution.

The electroplating production line mainly uses liquid medicine:

Metal electroplating includes additives, brighteners, film treatment agents, passivating agents, sealing agents, pre-treatment, etc. The color can also be varied, including color zinc, blue white zinc and black zinc, which can be configured according to customer needs.

Due to the complex composition of the wastewater produced by the production line of the factory, if mixed together, the amount of water is large, the concentration of pollutants is high, and the wastewater of different properties has different reaction conditions to the treatment process, which will increase the investment and operation costs. Therefore, different wastewater should adopt different treatment methods: Cr6+in chromium wastewater should be restored to Cr3+; Cyanide wastewater contains a large amount of cyanide, which must be completely oxidized; Zinc and pickling wastewater has high acidity and low pH value, which can remove various heavy metals and is being discharged.