Electroplating equipment How to maintain the production line

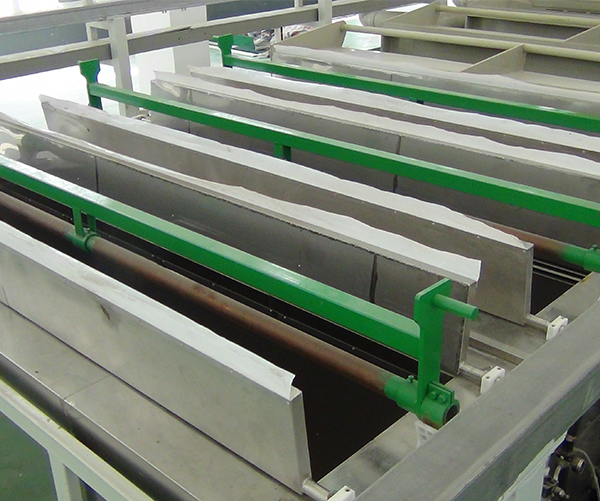

If the equipment is planned to be shut down for a long time, it should be maintained so that it will not be corroded and aged during the shutdown. To achieve: clean the road surface, clean the water on the ground, keep the road surface dry, and keep the machines, water tanks, cranes, and pendants clean and dry; All motors shall be wrapped with fresh paper for protection; All bearings shall be filled with lubricating grease to prevent rust; The liquid medicine in all pipelines shall be cleaned; The liquid medicine in the filter bucket of the filter shall be cleaned; Take out the filter element and clean it; All heaters in the tank shall be cleaned to remove stains and keep dry.

The electroplating equipment used in the production of printed circuit boards will be different due to different production processes and different manufacturers. Therefore, there will be some differences in maintenance methods, but the equipment must be maintained timely and correctly. The maintenance and repair of equipment cannot be ignored because of catching up with the production schedule and output. Only correct and timely maintenance can ensure the normal operation and stable performance of the equipment and ensure the production output and quality.

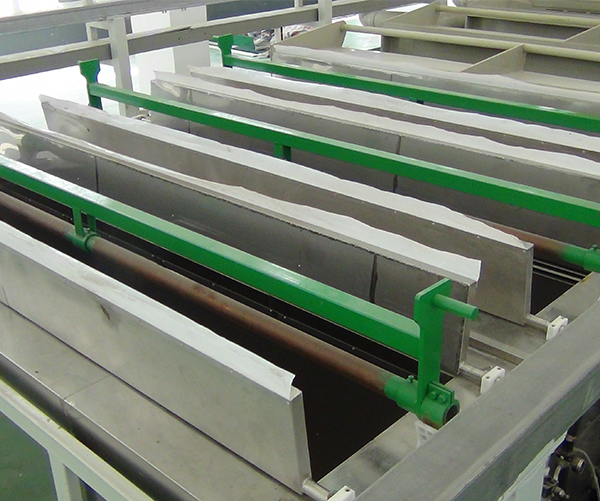

What is the production process of automatic electroplating production line?

1. The test run of the automatic line must be carried out before production, and the operation of the automatic line must be checked at any time under production conditions.

2. Check the temperature, current and other conditions of each slot position at any time during production, and solve problems in time if any.

3. The tooling and current are based on different tooling and current.

4. After the process and equipment are adjusted, the thickness of the first groove parts must be checked, and batch production can be carried out after they are qualified.

5. Timely fill in the process record under the production conditions, and fill in the stop work order in case of equipment failure.