Electroplating wastewater treatment equipment Zero emission process

This zero discharge process is applicable to comprehensive sewage enterprises that require zero discharge of classified air pollutants or have no pollution discharge permit for small water flow. The waste water is mixed and collected into the multi effect ion exchange method to remove some metal cadmium. After the cleaning solution is collected and mixed into the electric flocculation, the pH is adjusted and settled. After the DF equipment further removes various air pollutants, it is extracted by the ro2 extraction equipment. The waste water can reach about 50% of the recovery and utilization, and the concentrated water enters the subsequent solar power generation drying equipment to achieve zero discharge.

Zero discharge of electroplating wastewater Process introduction

The development trend of electroplating wastewater treatment in the 21st century will be to implement zero discharge in an all-round way. To achieve this goal, we must do something: centralize the decentralized galvanizing plants into the electroplating process center, reduce the engineering cost of equipment, and directly form a detailed closed cycle of cleaning water with the automatic technology electroplating production line and zero discharge equipment. If fully implemented, it will not only eliminate the pollution of electroplating wastewater, but also save a lot of water for human benefit.

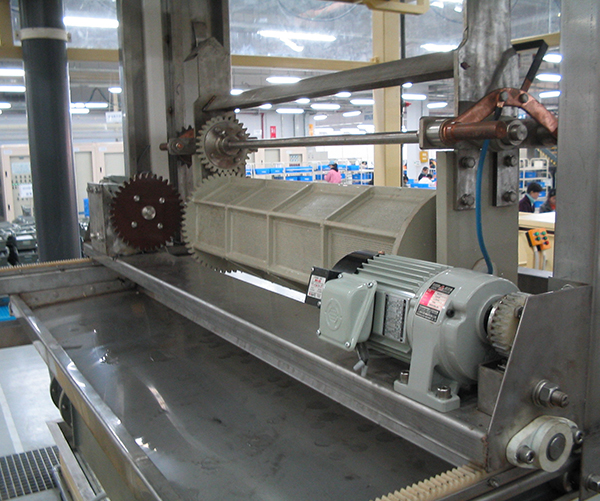

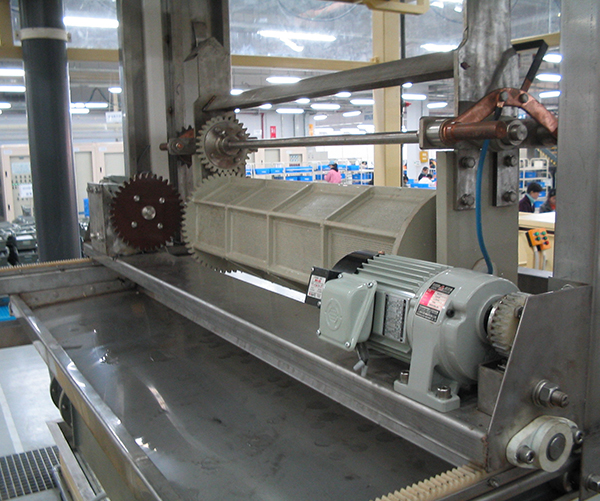

The purchase and utilization of electroplating process washing water is an important way for the electroplating process industry to reduce operating costs and reduce pollution. Our company uses the special separation function of membrane separation technology and purchases precious metals in the electroplating process washing water. Through the serial and parallel connection of multi-purpose reverse osmosis membrane and nanofiltration membrane, the final sewage reuse rate is 95%, The remaining 5% thick liquid is dried by bottom pressure vacuum pump MVR or (single/double effect) air conditioning evaporator or solar power generation. By reducing the air pressure in the air conditioning evaporator, the boiling point of waste water is reduced, and the gas water is separated at 50~70 ℃. The purity of volatile condensate is close to the standard of pure water, which can be used at the water point of production line for pretreatment and immersion. The remaining thick liquid crystals are extracted. After the concentrated solution is extracted to a certain concentration, it can be returned to the tank for use or taken away for food delivery; Crystals are outsourced, and precious metal cadmium crystals can be sold for delivery. By combining the three processes of chemical treatment, physical membrane extraction and evaporative crystallization, the "zero discharge" of sewage is ensured

Process characteristics of electroplating wastewater zero discharge process

1. Sewage recycling and utilization, reducing the amount of soaking water, can further treat sewage to meet the requirements of "zero discharge", reduce the scale of biochemical and organic chemical treatment, and help enterprises expand production.

2. The recovery and utilization of effective metal positive ions will enable enterprises to achieve environmental protection and economic benefits at the same time.

3. The metal cadmium sewage is converted into solid waste for treatment through evaporation crystallization, eliminating the fear of unqualified sewage discharge.

4. The process mainly adopts multi-purpose membrane concentration equipment, which is highly automated and easy to use.

5. The process strongly supports the national environmental protection requirements and integrates the design requirements of future environmental protection.